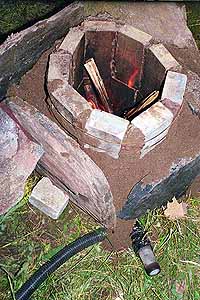

| Date : June 2001 Experiment : 1 Location : L'Anse Aux Meadows NF Team : Parks Canada Consultants (1) Furnace : Norse boxed bowl - stone slab sides, clay sealed, sod backed - no tap arch Size : 35 cm x 30 x 50 H (square) Source : based on LAM (theoretical) Tuyere : 25 mm ID steel pipe Placement : 5 cm above floor - 3 cm in from wall - angle slightly up Bellows : standard Norse double chamber Air : (E) 2 L per stroke - (E) 120 L per minute Charcoal : 8 kg broken hardwood Consumption : NR Ore : LAM bog ore - 5 kg (roasted) @ 62 % Fe Sequence : ore added as one large charge Duration : about 2 hours (plus preheat) Result : small slag mass - some small iron 'prills' (total 100 gm) - test as high carbon (cast iron) Notes : a number of basic errors, consider equipment test : - charcoal allowed to burn down to half way - ore placed on raft of bark - air flow not constant (cycles temperature) - low pressure / poor penetration of air - sequence too short |

|

| Date : May 2002 Experiment : 2/D1 Location : Wareham ON Team : DARC (2) + Dr. Kevin Smith Furnace: Norse boxed bowl - stone slab sides, clay sealed, sod backed - no tap arch Size : 30 cm x 30 x 40 H (square) Source : based on LAM (theoretical) Tuyere : 25 mm ID steel pipe Placement : angle slightly up Bellows : standard Norse double chamber Air : (EE) 1.2 L per stroke - (EE) 120 - 72 L per minute Charcoal : 22 kg broken hardwood Consumption : NR Ore : St Lunaire bog ore - 6 kg (roasted) @ 59 % Fe - mix of 2.8 ore / 2.5 scale / .7 sand Sequence : ore added as three large charges Duration : about 8 hours (plus preheat) Result : 2 kg slag mass - total 4.3 kg magnetic slag recovered Notes : a number of basic errors - use of large amount forge scale - extremely low air volume - low pressure / poor penetration of air - air flow not constant (cycles temperature) |

|

| Date : June 2003 Experiment : 3/D2 Location : Wareham ON Team : DARC Furnace : Early Medieval Medium Shaft - cylindrical cob with refractory liner - tap arch - fire brick base Size : 27 cm taper to 24 x 90 H Source : suggested by Sauder & Williams Tuyere : 25 mm ID steel pipe Placement : (E) about 20 cm from base - about 5 cm in from wall - angle at 15 down Bellows: vacuum blower Air : NR Charcoal : (E) 50 kg broken hardwood Consumption : about 1.5 kg charcoal every 12-15 minutes Ore : Virginia rock ore - 8 kg (roasted) @ 66 % Fe Sequence : ore added as 6 x 1.5 kg charges Duration : about 4 1/2 hours (plus preheat) Result : - initial liquid slag (faylite) tapped - burn through crashes sequence Notes : Generally sequence is closer to correct - slag bowl forms too high - slightly reduced air volume - incorrect tuyere angle |

|

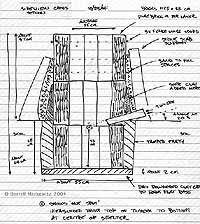

| Date: June 2004 Experiment : 4/D3 Location : Wareham ON Team : DARC + Mike McCarthy / Mark Pilgrim Furnace : Norse Boxed Short Shaft - cylindrical cob backed with stone slab and sand - no tap arch Size : 25 cm tapers to 20 x 50 H Source : suggested by Crew Tuyere : 25 mm ID steel pipe Placement : 2 cm from base - about 5 cm in from wall - angle at 15 down Bellows : initial Norse double bag / various Air : initial 2.2 per stroke / at 130 per minute / various Charcoal : (E) 19 kg broken hardwood Consumption : about 1.5 kg charcoal every 12-15 minutes Ore : Virginia rock ore - 7 kg (roasted) @ 66 % Fe Sequence : ore added as 7 x 1 kg charges Duration : about 6 hours (plus preheat) Result : slag masses only Notes: - Clay slumps during smelter construction - moves tuyere to incorrect position, too close to floor and shallow angle. This 'drowns' air flow. - Air system failures lead to fluctuating temperatures - Attempt to cut new tuyere unsuccessfully |

|

| Date : October 2004 Experiment : 5 Location : Cooperstown NY (Early Iron 1) Team : Michael Mahoney / Millard Wyman Paul Burdon / Elizabeth Hendrix Furnace : Norse Short Shaft - cylindrical cob set in earth trench - no tap arch Size : 28 cm x 60 H Source : suggested by earlier experiments Tuyere : 25 mm ID steel pipe Placement : 15 cm from base - about 3 cm in from wall - angle at 15 down Bellows : Norse double bag Air : 2.2 L per stroke - at 130 L per minute Charcoal : 100 L broken hardwood Consumption : about 6 L charcoal every 15 minutes Ore: Virginia rock ore - 8 kg (roasted) @ 66 % Fe Sequence : ore added as 5 x 1.5 kg charges + .5 reduction Duration : about 4 hours (plus preheat) Result : 'pre bloom mass' Notes : Air cut during operator changes and short smelter repairs - Generally structure successful - Air flow still low - Longer sequence required to develop larger bloom |

|

| Date : October 2004 Experiment : 6/D4 Location : Wareham ON Team : DARC Furnace : Econo Norse - firebrick backed with sand set in earth trench - no tap arch Size : 30 cm x 70 H Source : suggested by earlier experiments Tuyere : 25 mm ID steel pipe Placement : 20 cm from base - about 3 cm in from wall - angle at 20 down Bellows : vacuum blower Air : 550 L per minute Charcoal : 110 L broken hardwood Consumption : about 6 L charcoal every 12 - 15 minutes Ore : Virginia rock ore - (EE) 8 kg (roasted) @ 66 % Fe Sequence : ore added as 8 x 1 kg (E) charges Duration : about 5 1/2 hours (10 hours total) Result : 2 kg bloom - high carbon (cast iron) Yield : EE 25% Notes : Air cut (electrical problems) at pre-heat only - Successful creation of small bloom - Air flow still a bit low - Longer sequence required to develop larger bloom |

|

| Date : February 2005 Experiment : 7 Location : Lexington VA (Smeltfest 05) Team : Gangue aux Fer (3) Furnace : Econo Norse - firebrick backed with sand set on plinth - tap arch Size : 25 cm x 60 H Source : DARC 10/04 Tuyere : 25 mm ID 1/8" formed copper Placement : 18 cm from base - about 5 cm in from wall - angle at 20 down Bellows : vacuum blower Air : 815 L per minute Charcoal : 85 kg broken hardwood Consumption : about 2 kg charcoal every 10 minutes 5.3 m/kg Ore : Virginia rock ore - about 35 kg (roasted) @ 66 % Fe Sequence : ore added about every 10 minutes as small charges .5 - 2 kg 8.9 m/kg Duration : about 7 hours (not including preheat) Result : 6.5 kg bloom - (not tested) Yield : 18 % Notes : - Successful creation of mid sized bloom - tap slag recycled |

|

| Date : February 2005 Experiment : 8 Location : Lexington VA (Smeltfest 05) Team : Vince Petty / Vandy Simpson Furnace : Econo Norse - firebrick backed with sand set on plinth - tap arch Size : 25 cm x 60 H Source : DARC 10/04 Tuyere : 25 mm ID 1/8" formed copper Placement : 18 cm from base - about 5 cm in from wall - angle at 20 down Bellows : vacuum blower Air : 815 L per minute Charcoal : 85 kg broken hardwood Consumption : about 2 kg charcoal every 10 minutes 4.4 kg/m Ore : Virginia rock ore - 28 kg (roasted) @ 66 % Fe Sequence : ore added about every 10 minutes as small charges .5 - 2 kg 10.7 m/kg Duration : about 7 hours (not including preheat) Result : 7.5 kg bloom - (not tested) Yield : 27 % Notes : - Successful creation of mid sized bloom - tap slag recycled |

|

| Date : May 2005 Experiment : 9 Location : Wareham, ON Team : OABA / Neil Peterson / John Burton Furnace : Econo Norse - firebrick backed with sand, set on plinth - tap arch Size: 25 cm x 60 H Source : DARC 10/04 Tuyere : 25 mm ID schedule 40 pipe Placement : 20 cm from base - about 5 cm in from wall - angle at 20 down Bellows : electric blowers / rotary hand Air : inconsistent flow Charcoal : 67 kg broken hardwood Consumption : about 2 kg charcoal every 10 minutes 6.0 m/kg Ore : Stelco taconite - 21.5 kg (roasted) @ 65 % Fe Sequence : ore added about every 12 minutes as small charges .75 - 3 lbs 14.8 m/kg Duration : about 7 hours (not including preheat) Result : 9.5 kg bloom - (estimated) Yield : 45 % E Notes : - Successful creation of mid sized bloom - tap slag recycled |

Photo by Neil Peterson |

| Date : June 2005 Experiment : 10/D5 Location : Wareham, ON Team : DARC smelt demo team Furnace : Norse Short Shaft - clay cob with stone slab support - tap arch Size : 25 cm x 60 H Source : suggested by earlier experiments Tuyere : 25 mm ID schedule 40 pipe Placement : 16 cm from base - about 5 cm in from wall - angle at 20 down Bellows : large double bellows / electric blower Air : 600 l / min (estimated) Charcoal : 38 kg broken hardwood Consumption : about 2 kg charcoal every 10 minutes 5.7 m/kg Ore : Stelco taconite - 10.9 kg (roasted) @ 65 % Fe Sequence : ore added in variable sequence (10 - 20 min) as small charges .75 - 2.25 lbs 10.9 m/kg Duration : about 7 hours (not including preheat) Result : 3 kg bloom - (estimated) Yield : 28 % E Notes : - Successful creation of historic sized bloom - extreme hot weather limits use of bellows |

Photo by Neil Peterson |

| Date : September 2005 Experiment : 11/D6 Location : Annapolois Royal NS Team : DARC smelt demo team + Mark Pilgrim Furnace : Norse Short Shaft - commercial clay cob with stone slab support - tap arch Size : 25 cm x 60 H Source : suggested by earlier experiments Tuyere : 25 mm ID schedule 40 pipe Placement : 24 cm from base - about 5 cm in from wall - angle at 20 down Bellows : large double bellows / electric blower Air : no data (shift to forced air for last third) Charcoal : 47 kg broken hardwood Consumption : about 2 kg charcoal every 10 minutes 30.5 m/kg Ore : Stelco taconite - 10.9 kg (roasted) @ 65 % Fe Sequence : ore added in variable sequence (10 - 20 min) as small charges .75 - 2.25 lbs 9.2 m/kg Duration : about 7 hours (not including preheat) Result : cast iron mass ? 2 kg? no data available on size Notes : use of high purity taconite means no silica - use of high temperature clay means no silica - no silica means no carbon control - exit valves required on bellows ?? |

Photo by Neil Peterson |

| Date : September 2005 Experiment : 12 Location : Copperstown NY (Early Iron 2) Team : Elizabeth Hendrix / Toby Bashaw Furnace : Flue Tyle - commercial tile reinforced with wire - tap arch Size : 25 cm square x 60 H Source : developed by Sauder & Williams Tuyere : 25 mm ID forged copper Placement : about 24 cm from base - 5 cm in from wall - angle at 20 down Bellows : electric blower Air : plus 1000 L/min? Charcoal : 110 lbs primary sequence / no data for balance* Consumption : about 5 lbs charcoal every 10 minutes Ore : Virginia Rock Ore - about 35 lbs * @ 66 % Fe Sequence : ore added in variable sequence (8 - 12 min) as small charges .75 - 2.25 lbs Duration : about 7 1/2 hours * (not including preheat) Result : Two bloom masses Secondary at 3.4 KG (Yield uncertain = 20 % E) Notes : Main smelt sequence abandoned at 6 1/2 hours Smelt assumed, produced secondary 'salvage bloom' * no clear records kept for secondary sequence |

Photographer Unknown |

| Date : November 2005 Experiment :13/D7 Location : Wareham, ON Team : DARC Furnace: Norse Short Shaft - clay cob with stone slab support - tap arch Note - reuse of furnace from June 05 Size : 25 cm x 60 H Source : suggested by earlier experiments Tuyere : 25 mm ID ceramic kiln support Placement : 16 cm from base - about 5 cm in from wall - angle at 20 down Bellows : vacuum blower Air : 600 l / min (estimated) Charcoal : 79.5 kg broken hardwood Consumption : about 2 kg charcoal every 10 minutes 3.6 m/kg Ore : Stelco taconite + Virginia Rock Ore 19.8 kg (roasted) Sequence : ore added in variable sequence (7 - 10 min) as small charges .75 - 2.25 lbs 10.7 m/kg Duration : about 6 1/4 hours (not including preheat) Result : 4.3 kg bloom Yield : 22 % Notes : - Successful creation of historic sized bloom - Success in patching and re-firing smelt |

|

|

to view the 2006 series |

|

|

(1) Parks Canada / L'Anse aux Meadows Mark Pilgrim Assisting Birgitta Wallace / Arne Espelund |

Note: will require an external internet connection Lee Sauder Mike McCarthy DARC - Iron Experiments |

(2) Dark Ages Re-creation Company Core Team: Kevin Jarbeau / Dave Cox Neil Peterson Assisting: Ken Cook / Marcus Burnham Karen Peterson / Vandy Simpson Gus Gissing |

|

(3) Gangue aux Fer Lee Sauder / Skip Williams Mike McCarthy and after 2005 - Dick Sargent Assisting: Elisabeth Sauder & Vandy Simpson |

Photo by Elisabeth Sauder |