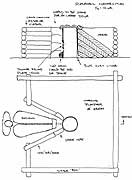

The proposed reconstruction of the Hals smelter.

For a better understanding of the experimental sequence involved, readers are

referred to the discussion of the evidence from Hals, Iceland - 'Working

towards a Viking Age Icelandic Smelter'.

|

||

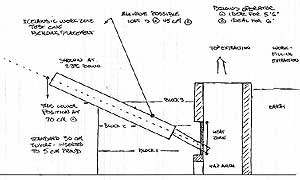

Front View showing some important theoretical measurements. |

Plan View showing construction details and working areas. | Cross Section showing bellows and front working area. |

A simple plan view of the initial situation with

layout of the Icelandic smelter indicated. |

Photo of the same view after the rail ties had been

placed. |

With the working slot lined with concrete blocks. |

Showing the rough cylinder cut into the earth bank.

Again the rock filled soil at Wareham made getting a clean edge and correct

size and shape impossible. |

The first course of clay cobb laid in place. The approximate

wall thickness was kept to 5 cm. The brick used to frame in the tap arch

can bee seen. |

At the completion of the third course. The sand used

to stabilize the interior shape can be seen. |

The finished cylinder, within its ring of stones. |

With hole for plate cut, before removing the ashes

from the drying fire. |

Down the inside of the smelter with the bellows plate

installed. |

A view of the exterior of the smelter with bellows

plate installed. |

Setting Up for the Smelt:

As one of the objectives was to determine the work pattern (and problems) with

the layout including a human powered bellows, the space for this equipment was

determined by positioning the frame required to support a Norse style double

bellows of suitable size. The space was then simulated with a full sized cut

out in the same location. The standard electric blower was then use to provide

the required air, with a flexible pipe attached to the normal T fitting. The

working end consisted of one of the commercial ceramic tube tuyeres (2.5 cm

interior diameter). The measured angle on the air pipe was 15 degrees down.

The gap between the tip of the air pipe and the surface of the bellows plate

was established by sound (adjusting for the loudest and 'throaty-est' roar).

Once this was established, the air pipe was wired into place on the wooden frame.

The resulting gap was about 3 - 4 cm determined with an air flow estimated at

740 litres per minute.

The final measurements of the finished smelter. |

With the new experimental double bellows in place

on the frame. |

Frame remains, with the standard forced air system

in place. |

The view underneath the frame towards the tap

arch. |

(Go on for the Experimental Data Sheet )

|

|

| After adding about 4 kg of rock ore, showing cracking of the clay around the edges of the bellows plate (not in itself critical). | After adding about 8 kg of the rock ore. The skim of glass freezing in the air blast on the top of the slag bowl is clear to see to the left. | After some frantic activity - conversion to an insert style tuyere to save the smelt | After the heat has returned to correct levels and the frame removed the tap arch is cleared and the furnace begins to self tap. |

| <object width="425" height="344" align="middle"> <param name="movie" value="http://www.youtube.com/v/ilZitcYyVoA&hl=en&fs=1"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/ilZitcYyVoA&hl=en&fs=1" height="200" align="middle" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true"></embed></object> |

||

At the top of the furnace, just into the burn down

phase |

The finished bloom, after one compaction series. |

A brief overview of the smelt |

An overall view of the entire working area. |

A closer view of the damage to the smelter itself. |

| The inner surface of the smelter, at the rear (away from the tuyere) at base level. | The inner surface of the bellows plate, with the position of the tuyere at the top. | A close up of the clay liner, just at the top edge of the bellows plate. |