| 'But

If You Don't Get Any IRON...' Towards an Effective Method for Small Iron Smelting Furnaces. Published on in the EXARC Journal : issue 2012/1 Available as a PDF |

|

| Standardized

Reporting

of Experimental Iron Smelting - a modest (?) proposal This article was sparked by discussions leading up to the orginally scheduled 2020 Woodford Furnace Festival (Ireland). Completed as a 'semi - academic' format, it was submitted and published in the EXARC Journal : issue 2021/1 Available as a PDF |

|

|

Stacking Up

On constructing clay furnace walls This report is a consideration of

what has been learned from the construction of a large

number of clay mixture furnaces over the last two

decades.

This includes some observations that relate back to the continuing experimental series based on the Viking Age furnaces excavated at Hals, Iceland. : Prepared August 2021 Continue to : Stacking Up

|

|

Smelting with Sven & Yorgi A 'thought experiment' How would the process of smelting iron be described - in the Viking Age? Download Sven & Yorgi (PDF) |

|

- made from easily available materials :

|

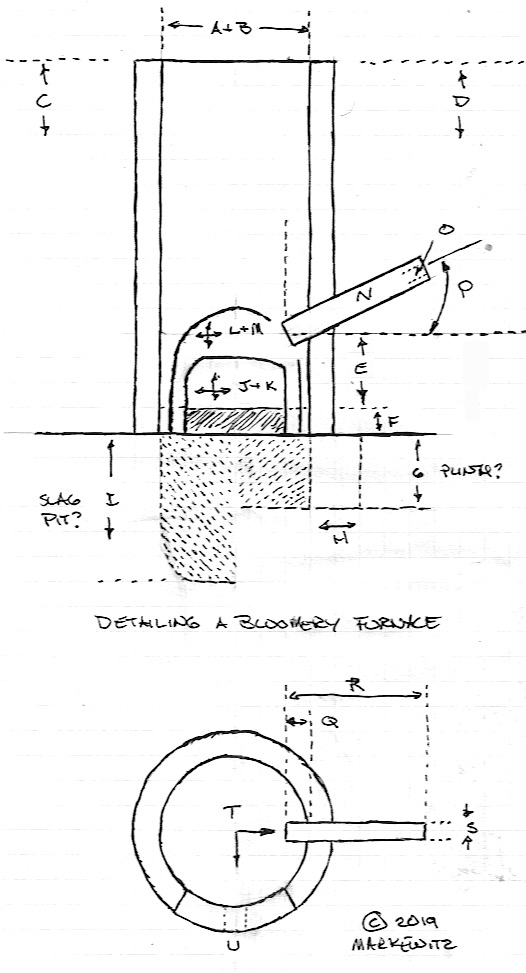

the Econo Norse Smelter

|

|

|

the Flue Tyle Smelter

|

|

|

the Norse Short Shaft

|

|

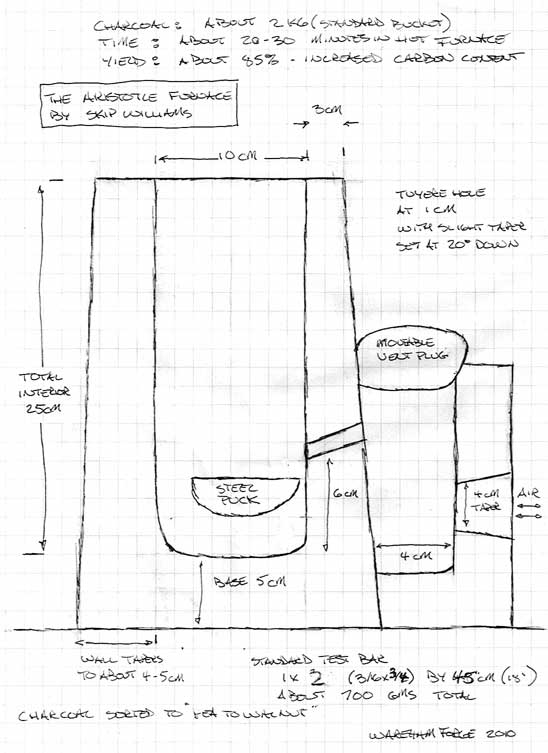

| the

Aristotle Remelting Furnace A handout on building and running this table top sized furnace, which can be used to modify the carbon of any scrap iron metals, Download Aristotle Furnace Handout (PDF) Building the Furnace (blog post / photo essay) |

|

|

45 Gallon Drum Charcoal

|

| Is my BLOG - on it you will find a regular series of

short postings on various aspects of Experimental Iron

Smelting |

|

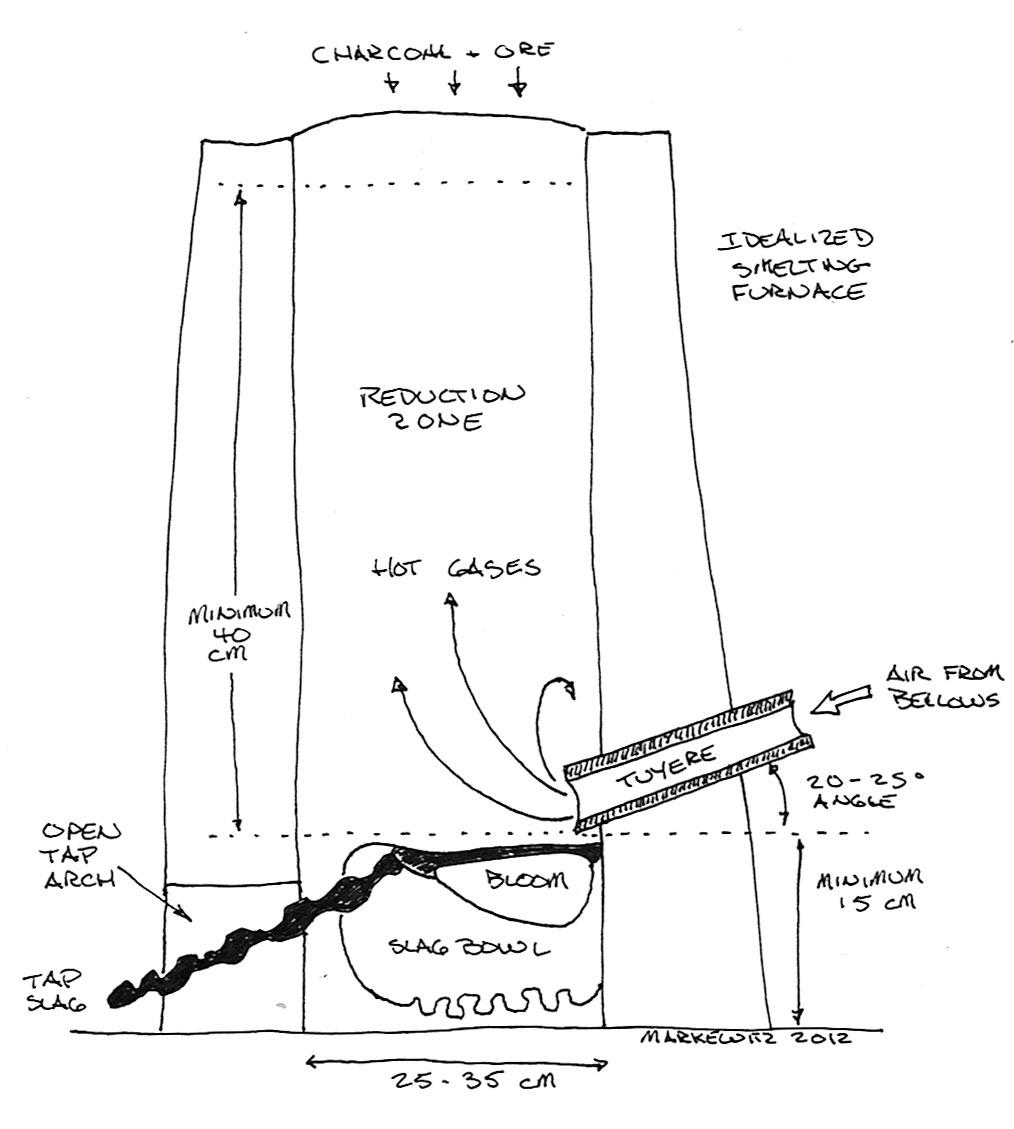

Introduction

to Smelting Iron

This HANDS ON course is

dependant on registrations This roughly 20 hour session will involve the student in the construction and operation of the 'Short Shaft' iron smelter. On Friday evening students will cover the theoretical and historical background of smelting iron: ores, furnaces, process, equipment. Saturday students will build the furnace itself, plus prepare charcoal and ore. An early start for a LONG day Sunday will start with the pre-heating the furnace. The actual process of the smelt takes roughly 6 - 8 hours. After this, the resulting iron bloom will be extracted from the furnace, and given a primary consolidation. The iron produced will be cut to sections and shared between the participants. This program does not require any previous metalworking experience, and is of interest to students of history as well as blacksmiths. |

|