These pieces represent only a few of

the large number of knives, tools and weapons I have

made since the late 1970's. This has included

everything from small 'hide out' knives to full sized

'bastard' swords - working tools to combat blades.

From the very first, my interest has been the blade as

cutting edge - not so much as a decorative object.

• I have remained most interested in the wide

possibilities of aggressively forged blade

shapes. (Rather than the more limited 'straight ground

from bar' profiles so common to 'knife makers')

• Although I have worked extensively with layered

steels, my work centres on the more dramatic potentials

of Norse inspired, multiple twisted bar, 'Pattern

Welding'.

• Even when working with more conventional flat stack

('Damascus'), I prefer the randomly distorted lines

created buy aggressively hand hammered billets.

• To maintain durable cutting edges, most layered steel

billets are then forged welded to a solid carbon steel

core (creating a more functional hard edge).

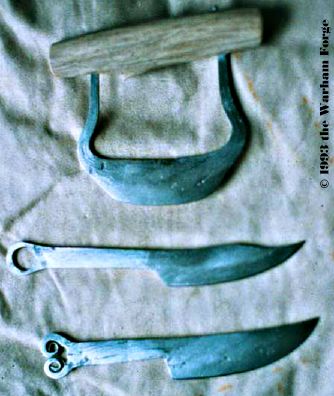

• Many knives feature 'one piece' construction, as I

have less interest in the 'knife as jewellery' aspect

seen in much contemporary knife making.

Objects are shown from most recent to

earliest work.

Samples of Past Work

are also seen on

'Custom BLADESMITHING'

Finished Replica  Comparison with Artifact  Full view with Handle |

French Trade

Axe

2013 bloomery iron with inset carbon steel edge modern (commercial) ash handle $ 800 - this item available One of the few actual artifacts I have in my collection is a French Trade Axe. It is of the 'Biscayne' pattern, a type made specifically for the Fur Trade. The object was found near Angus Ontario, not far from the Nottawasaga River - the route from Lake Ontario north towards Ste Marie Amoung the Hurons. This pegs the earliest deposit date to about 1600 +. This type of axe stopped manufacture about 1760, so the most recent deposit date is not likely beyond the late 1780's. I decided to make a replica of the artifact, using my own bloomery iron. This would match the original metal, the forging processes, as well as the profile of the axe. In the end I had a bit less material to start with than in the original, and my forged shape is not quite identical to to artifact. Finished dimensions:

head weight = 1050 gm width at edge = 9.5 cm total length = 20 cm thickness at eye = 2 cm width of eye = 5 cm handle length = 51 cm |

|

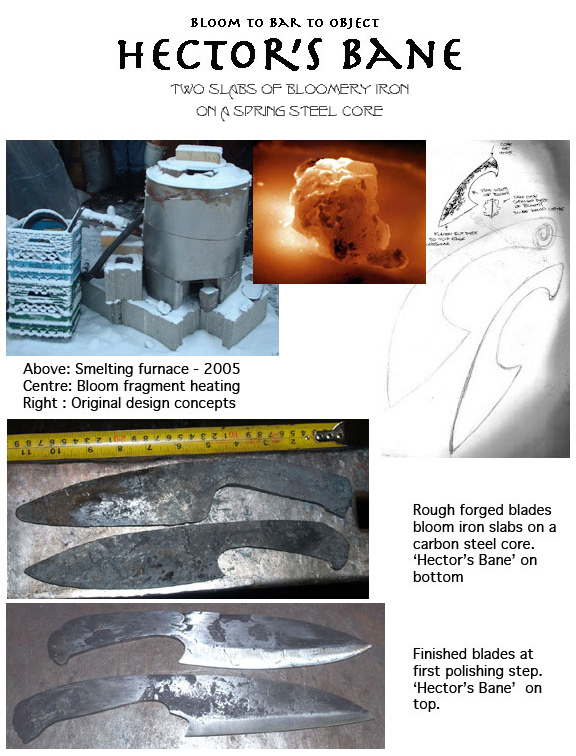

'Hector's Bane' bloomery iron /

carbon steel core 'Hector's Bane' shows a

combination of influences: After some consideration, the polished blade was

lightly etched. This resulted in a 'fog'

colouration over the surface, a result of the

variations in carbon content within the original

bloom. |

|

||||

|

Norse Ship

Building Tools

Spring 2008 for Parks Canada In 2008 I was approached by Parks Canada to make a complete set of Norse building tools for the living history program at L'Anse aux Meadows NHSC. (I have had a long association with this site and the Norse Encampment program.) I was able to undertake additional research in Denmark into historic prototypes. A fuller description of this

project, and the tools created, is available HERE

|

|

Pattern Welded Norse Seax

Spring 2007 private commission The billet for this blade is primarily mix of

mild steel and a low nickel alloy called L6, along

with a layer of high carbon steel. The L6

simulates the use of meteor material in my

historic blades. (L6 is .5 % nickel and a middle

level .5% carbon - meteorites are closer to 5 %

Ni, but with no carbon). The initial stacks were

at 13 layers, these have been welded and folded to

four to give a 52 layer bar.

|

|

Pattern Welded Sgian Dubh

Spring 2006 private commission This is a custom knife created for a customer

who wanted to mark his upcoming wedding with a

distinctive heirloom object. |

|

Fall 2004 sold to private collection This is just one of a number of potential blade profiles I had designed for a customer in late 2003. The project involved creating a striking letter opener using the pattern welding technique. This particular profile, I had thought the most pleasing of the lot, was not the one the customer selected in the end. Latter (early 2004) I decided to make up a small billet into this blade. In keeping with its function as a letter opener, it has no carbon steel core and is only sharpened at the very tip. |

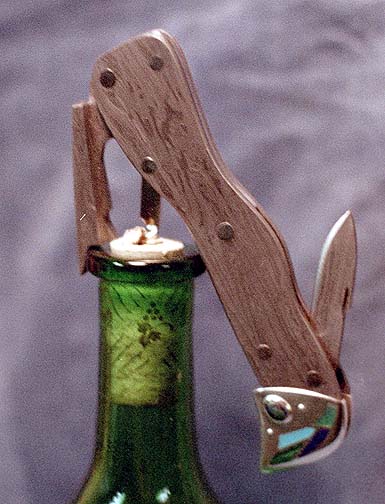

Layered Steel Opener private commission This unusual piece - a Layered Steel Bottle Opener , was ordered by a customer as a special gift for a friend. It follows the form and function of a wine bottle opener - cork screw and foil cutter. I worked together with silver smith Brenda Roy - who created the silver bolster block inlayed with semi precious stones. Overall the piece has an Art Nouveau feel in terms of colour and line. Completed in December of 2003. |

'Possibilities of Damascus' sold to private collection

'Possibilities of Damascus'

was created for the exhibit 'Traditions &

Innovations' in 2003. |

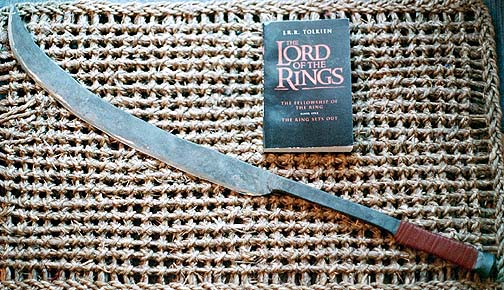

'Orc Knife' sold to private collection Orc Knife was a piece done at the very end of 2002, a couple of days after I had seen 'The Two Towers'. It was an experiment in a number of different ways. First - I had looked at the production designs used for Jackson's 'Lord of the Rings', and had tried to work in a similar style. Second - I had used the air hammer for about 90% of the forging, giving me good practice in shape generation on that tool. Third - this object was offered on sale over Ebay, my first experiment with that venue. |

|

'Sword of

Heroes'

sold to private collection

'Sword of Heroes' is a

Pattern Welded Short Sword produced in early

winter of 2000. |