|

The objects shown here represent a body of hand forged work by Artisan Blacksmith Darrell Markewitz that stretches back into the late 1970's (!). One of the dominant stresses to all my one of a kind pieces has been the individual designs. To speed up your trip, the objects have been loosely grouped by type, each group with its own page. |

|

|

|

|

|

& Candelabras |

|

|

& Fountains |

|

Home Accessories |

|

|

|

|

|

|

|

|

|

|

|

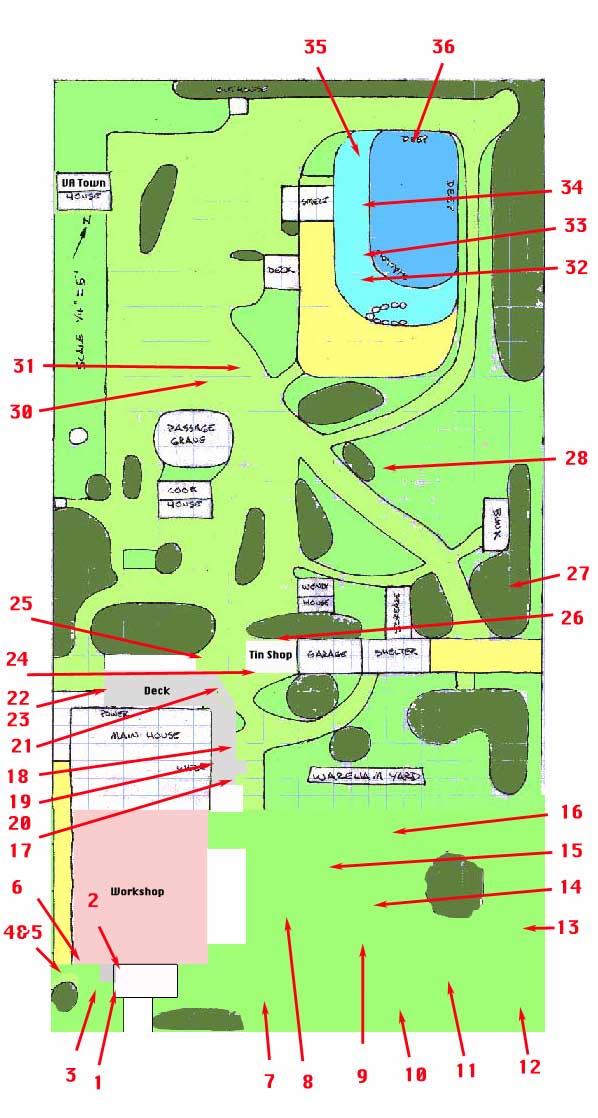

30

Years of Past Art Works Over time, any artist will slowly accumulate a body of pieces, which for one reason or another, never found a buyer. As is the case for many others, many of these are what I consider some of my best sculptural work. Rather than leave these hidden away to gather dust, over the last couple of years I have been mounting these around the tree spotted property at Wareham. For a look, go on to Yard Art Tour |

|

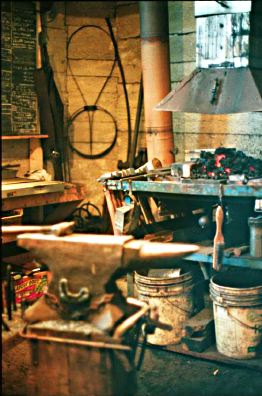

This is the heart of the operation - the forge itself.

You can clearly see the 225 lb 'London' pattern anvil that

is the main work surface. The primary forge is made of a

cast fire box set in a metal table. Although it still

burns coal, the air supply is an electric blower with both

a motor control and a sliding gate to modify the air

volume (thus heat.) Note the sliding hood suspended from

the ceiling - it can drop right down to the table and

there is a large extraction fan mounted on the roof to

force out the smoke. |

|