An evaluation of the Hals site

Starting assessment comparing the archaeology against what was then known of working methods. - Fall 2007

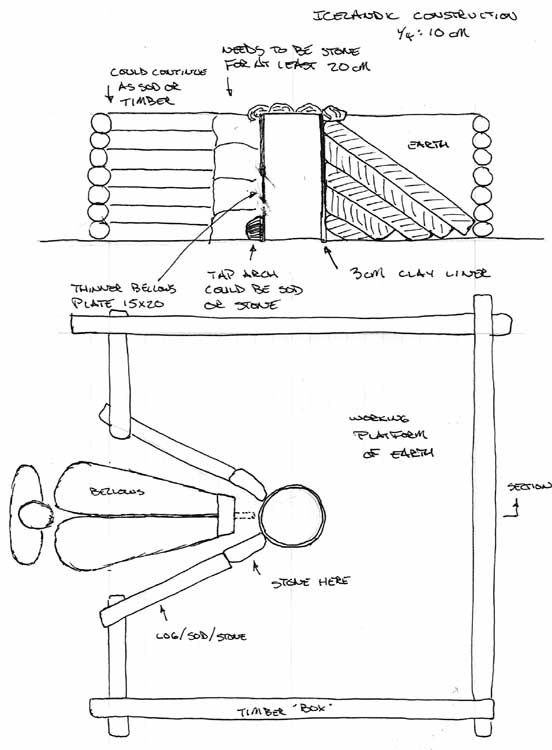

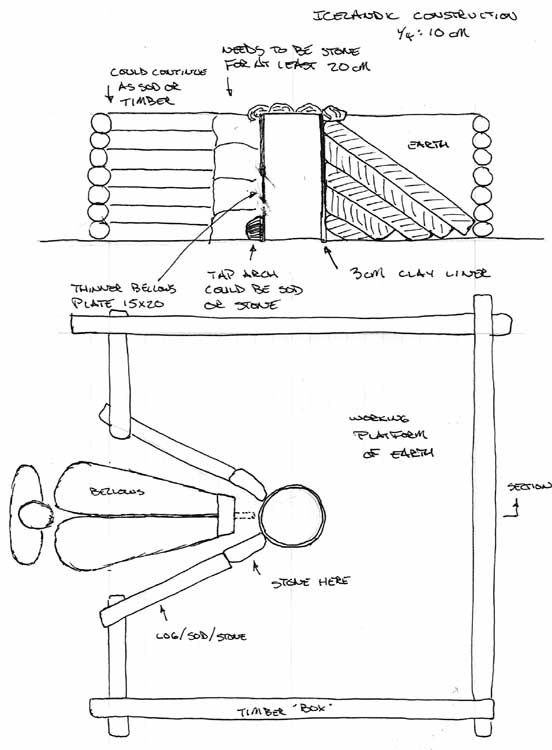

Icelandic Sod Walled Bloomery Furnaces

Based on the remains at Háls

| 'Towards an Icelandic Smelt' An evaluation of the Hals site Starting assessment comparing the archaeology against what was then known of working methods. - Fall 2007 |

|

| #26 - Icelandic 1

October 8, 2007 |

Written Report | Smelt Sequences experimental data |

Theoretical

Set Up field drawing |

|

| Base Constrution Construction Details Front Elevation field drawings |

Smelt in Progress video clip |

|||

| #27 / D13 - Icelandic 2

October 27, 2007 |

Written Report | Smelt Sequences experimental data |

Base

Construction Front Elevation Top View field drawings |

|

| #38 / D16 - Icelandic 3 Work Dynamic Test October 12, 2008 |

Written

Report detailed overview |

Smelt Sequence experimental data |

Existing

/ Elevation field drawings |

Front / Plan / Section theoretical layout |

| #39 / D17 - Icelandic 4 November 8, 2008 |

Written Report short overview |

Smelt Sequence experimental data |

Plan

& Elevation field drawing |

| #51 / D27 - Return to

Icelandic May 26 , 2012 |

Brief Report blog posting |

Smelt Sequence experimental data |

Layout Front Elevation field drawings |

Bellows Test experimental data |

| #60 / D28 - Icelandic 6 - 'Grass Sod' Fall 2014 to Summer 2015 |

Experiment Concept blog posting |

Furnace Build blog posting |

Front Elevation field drawing |

Input = Output experimental data |

| Experiment Overview blog posting |

Smelt Sequence experimental data |

Recovered Mass field drawing |

Recovered Bloom blog posting |

|

| #61 / D29 - Icelandic 7 'Grass

Sod' October 12, 2015 |

Detailed Overview DARC - Neil Peterson |

Smelt Sequence experimental data |

Front Elevation Base Construction field drawings |

|

| #70 / D30 - Icelandic 8 - 'Full Sod Build' Schweitzer / Amaranth October 29, 2016 |

Experiment Overview detailed report |

Smelt Sequence experimental data |

Furnace

Outline field drawing Front Elevation reconstructed |

Design & Intial Construction blog posting |

| #88 / D33 - Icelandic 9

Clay Test (P3-A) June 2021 |

Brief Overview blog post |

Smelt Sequence experimental data |

Furnace Plan Furnace Elevation field drawings |

|

| #89 / D34 - Icelandic

10 - Clay Repeated (P3-B) September 2021 |

Brief Overview With new air system builds blog post |

Smelt Sequence experimental data |

Furnace Repairs Elevation field drawing |

|

| #98 / D40 - Icelandic 11 - Return to

Icelandic November 2024 |

Experimental

Outline detailed report |

Smelt

Sequence experimental data |

Furnace

layout field drawing |

| #82 - Stone Block Furnace System Test June 2019 |

Furnace

Construction field drawing |

Smelt

Sequence experimental data |

Front

Elevation field drawing |

|

| #83 - Stone Block Slag Bowl Test October 2019 |

Smelt

Sequence experimental data |

Base

Setup field drawing furnace re-used |

||

| Smelt

Sequence experimental data |

furnace re-used |

|||

| #

87 / D32 - '65 for 65' October 2020 |

Experiment

Overview detailed report |

Smelt

Sequence experimental data |

Furnace Details field drawing |

Now with 70% Less Clay!Experiments with

Viking Age Icelandic Turf walled Iron Smelting

Furnaces

This presentation was part of the

'virtual' 2021 EAC12

Conference Experimental Archaeology.

Prepared with the assistance of Kevin P. Smith and Neil Peterson. Video on YouTube |

|

|

Icelandic Sod

Walled Iron Furnaces,

based on the Archaeology at Háls, Iceland This narrated Powerpoint style presentation was delivered (as recorded video) at the 2025 International Congress on Medieval Studies. This is an extension of the presentation above to include the November 2024 smelt, the last in this series. Video on YouTube |

|

|

Westward Viking -

Iron

From Norway to Iceland ... to Vinland This presentation was prepared for the 'virtual' 2020 Woodford Furnace Festival Video on YouTube Equipment problems prevented delivery |

|

| Into Phase 3 Continuing experiments with iron smelting based on Hals, Iceland This commentary is a re-evaluation of

the Icelandic series, looking again at the

archaeology, now with an additional 15 years of iron

smelting experience.

This includes discussion of how we are approaching the next series of experiments, testing elements suggested by the Viking Age furnace complex at Hals, Iceland : Prepared Summer 2021 Continue to : Phase 3 |

|

|

Stacking Up

On constructing clay furnace walls This report is a consideration of

what has been learned from the construction of a large

number of clay mixture furnaces over the last two

decades.

This includes some observations that relate back to the continuing experimental series based on the Viking Age furnaces excavated at Hals, Iceland. : Prepared August 2021 Continue to : Stacking Up |

|

|

Archaeology,

Experience and Experiment : with contributions by Neil Peterson

and Rey Cogswell

This is an expanded version of the formal paper

submitted for inclusion in the upcoming volume Can

These Bones Come to Life?, including additional

photographs - combining a number of individual reports

prepared over 2021. Continue to : Archaeology, Experience & Experiment |

|

|

Experiments with

Viking Age, Icelandic, in collaboration with Neil Peterson This is a 2021 modified version of the more complete formal paper, currently under preparation, not including the section to be contributed later by Kevin P. Smith. Presented here is a 'web integrated' text, describing in considerable detail the individual experiments, and including a larger series of images than are likely to be seen in the future published paper. Continue to : Experiments

with Icelandic |

|

|

|

|

|

|

Stone Slab with Blow Hole

Icelandic 1 - October 2007 |

Icelandic Work Dynamic Test

Icelandic 3 - October 2008 |