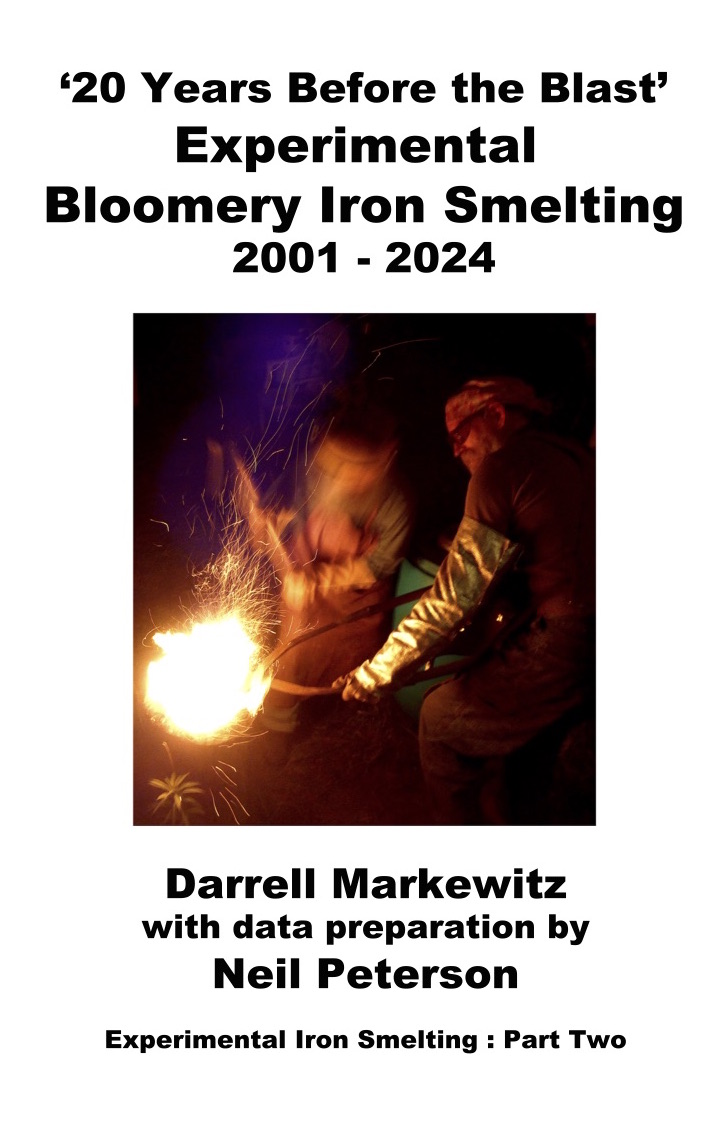

Experimental

IRON SMELTING

2001 - present

How did the Norse during the Viking Age make

iron blooms from bog ore?

Experimental Archaeology can give insight into the techniques

used in Northern Europe to operate direct reduction iron

smelting furnaces.

This is a record of over 100 bloomery iron smelts in the

ongoing series by Darrell

Markewitz,

assisted by members of the Dark Ages

Re-creation Company.

Wareham, Ontario, Canada is this centre for this practical

research into Norse methods for North America.

2026 : The original content has been

streamlined into individual topic sections.

This may result in repetition of some elements.

For the original version of this web site : HERE

Experimental Data

Table form, 45 elements for each individual iron smelt

Plus additional tables for specific experimental

objectives

Individual

Experiment Reports

Sequence Data / Furnace Layout / Description

As individual experimental series

| Vinland |

Icelandic

/ Hals |

Turf

to Tools |

Norse Bellows Air | Bog Iron Ore Analog |

|

|

|

|  |

Publications

List of books, journal articles, conference presentations,

commentaries

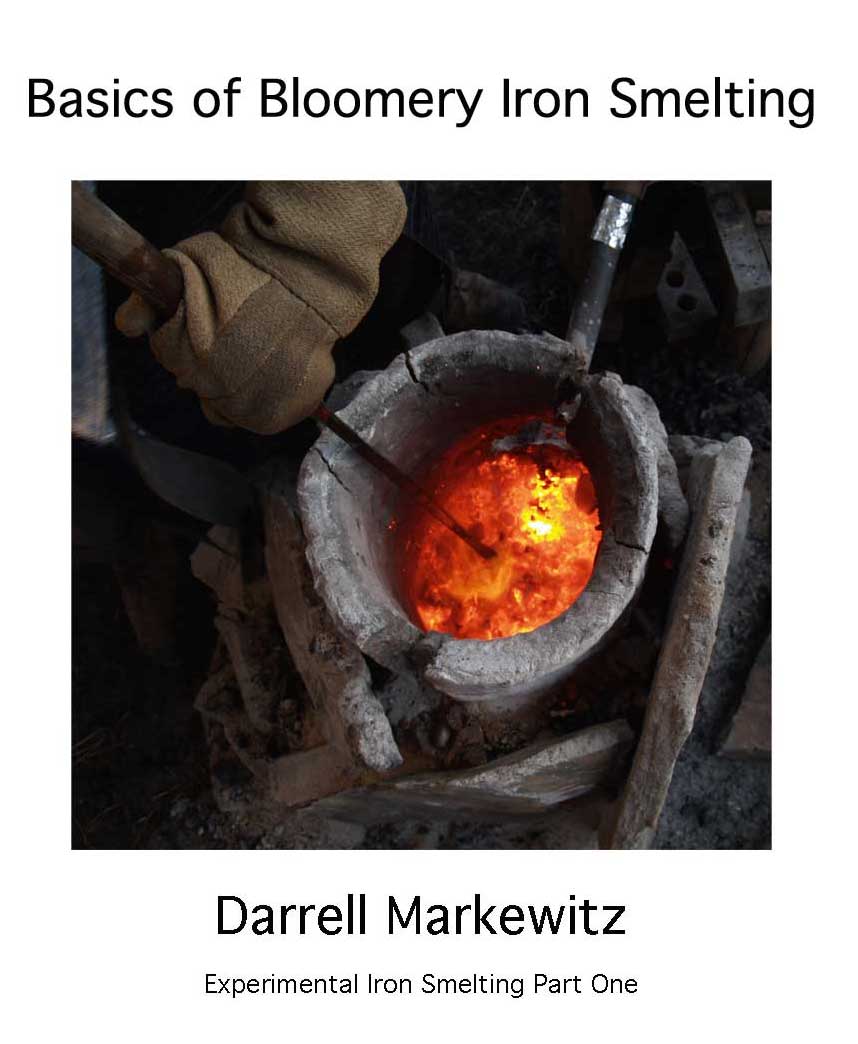

Practical Guides

Technique instruction for undertaking bloomery iron

smelting

Video

Illustrating specific iron smelts