| Welcome to the Wareham Forge,

the work of Artisan Blacksmith Darrell Markewitz of

Ontario Canada. Here traditional hand forged techniques

are blended with original custom designs to create

distinctive objects for garden or architecture. (What is

called 'wrought iron work' by some.) A specialist in the

Viking Age, creating reproductions for Museums and

re-enactors. Offering training courses various aspects of

Metalsmithing, plus instructional DVD's. |

|

|

pull out guide |

Aggressively Hand Forged

Bowls and Containers

'Bowls' as objects

represent a balance:

- If considered as things that can exhibit

more design than pure function, creativity can expand.- These are large enough pieces that a wide number of forging and decorative techniques can be employed. - They are not so large or massive that they are (often) overwelmingly time consuming to make. - They also represent the kind of object that will be considered as much for their appearance as their end use. - Taken together, bowls and other containers become things to be treasured, but not so precious to make them beyond the reach of most. There is some attempt here to present

pieces in chronological order.

|

|

forged and fabricated wrought iron & copper Fall 2008 $1200 - this item available " The body of the urn is composed of a number of individually hand forged strips of antique wrought iron. I saw samples of the basic technique employed by the Japanese blacksmith Takayoshi Komine at a workshop / demonstration two summers past. (Taka uses the method to make subtle oil lamps employed in the Tea Ceremony.) Actual historic wrought iron has been chosen for the construction because of its excellent forging characteristics and special durability. The metal itself is already some 150 years old — and should easily endure for centuries more. A fitting resting place for the memories of one past beyond us. " For more details on the thought behind

and creation of this object - Go on to a detailed

description

|

||

|

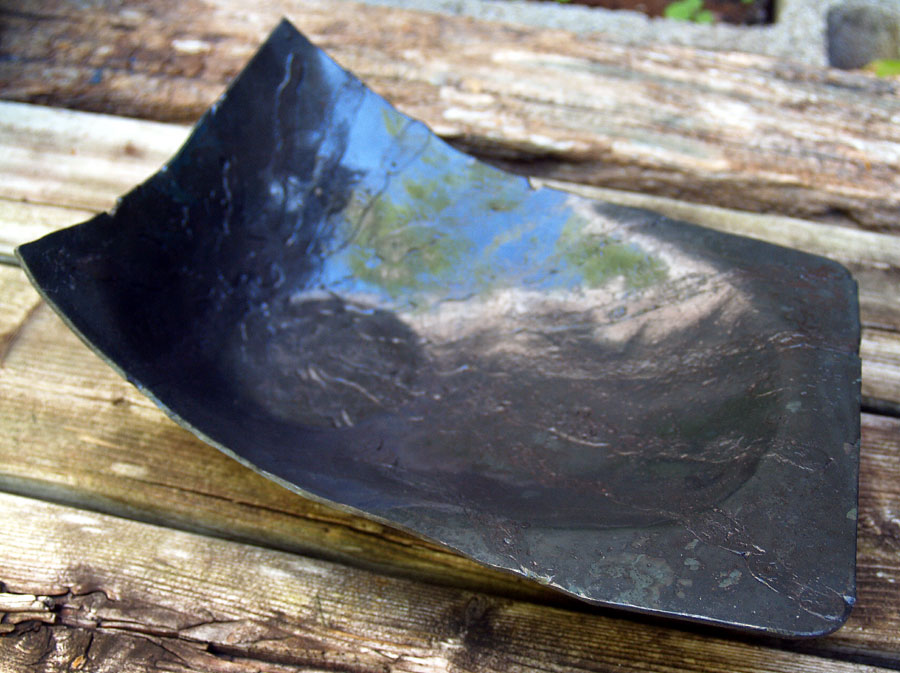

Winter 2011 welded then forged mild steel plate (private collection) Offcut Bowl was created for the 'Shadowbox' show to benefit the South Grey-Bruce Literacy Council. The object is about 10 x 10 in size, standing about 3 inches deep. The individual segments are in fact off cuts left over when I was cutting up some 1/8 inch thick plate I acquired as commercial scrap. Taking a clue from a method used by Japanese artisan Takayoshi Komine, the individual segments were MIG welded together on the back, then the weld beads ground smooth. The resulting flat form was then worked hot to dish it. More details available on 'Hammered

Out Bits'. |

||

|

Winter 2011 welded then forged mild steel plate $175 - this item available Here a series of plates were rough cut

with a torch. The individual plates are welded together,

in this case with weld seams deliberately rough and

applied on both the back, and visible top, surfaces. One

of these seams was folded 'backwards' to create the

ridge visible just off centre. Finally the attached

surface was forged to the bowl shape.

24 x 19 cm, top edge 8 cm high

|

||

|

Winter 2012 forged and welded mild steel (private collection) This smaller bowl is more true to the

basic technique employed by the Japanese blacksmith

Takayoshi Komin. A number of narrow but thick, uniform

length bars are welded on the back and ground flush. The

plate thus produced is then heavily hot dished to create

the bowl form.

16 x 12 cm, top edge 9 cm high

|

|

|

|

'Points' - Segmented Bowl 4 forged and welded mild steel plate (private collection) Again a series of narrow triangular shapes retain ragged edges from torch cutting. |

|

Winter 2011 patterned and forged mild steel plate (private collection) This piece served as a 'test of concept'

for a new decoration method I had stumbled upon. Lines

were laid on a piece of 1/8 inch thick steel plate.

After forging flat, the plate was then dished using

various rounding hammers and bottom forms. For this

piece, the top surface was wire brushed, then sealed

with satin varithane. The title is intended to be a kick

back to those who 'put a knott on anything - then call

it 'Celtic'.

|

||

|

Spring 2011 patterned and forged mild steel plate (private collection) Continues the series. On this piece, the

natural fire scale surface was left after forging, but

still sealed with varithane for functional use.

22 x 15 cm, top edge 10 cm |

|

|

|

Spring 2015 patterned and forged mild steel plate $ 200 - this item available More exploration of the

'lines' technique. Here there was less hammering over

the lines, leaving a more textured surface

25 x 20 cm, top edge 8 cm |

|

|

Off

Centre Bowl Spring 2015 patterned and forged mild steel plate (private collection) On this piece, the lines are

laid as a 'starburst' pattern, radiating from one side of

the original rectangular plate. The dishing process then

echoed this, creating an offset oval form. There is a

small flat sprial leg under the shallow side for support.

25 x 15 cm, top edge 7 cm |

|

|

Off Centre Bowl

Spring 2015 patterned and forged mild steel plate (private collection) The lines laid here are more

random in pattern. The starting plate was a pronounced

lens shape, with one edge rough cut by torch. In the

forging process, the shape created has a deep, flat

bottom, the points curved under.

20 x 13 cm, top edge 7 cm

|

|

|

'Starburst' Bowl

Spring 2015 patterned and forged mild steel plate (private collection) Another object using a regular

'starburst' pattern to the lines, here more symmetrical.

Also the use of a torch cut edge, but this time the ragged

notches smoothed before forging. The interior has been

both dished in, and the bottom raised up slightly

(ensuring a stable base).

about 30 x 20 cm, top edge 5 cm

|

|

|

Green Lines Bowl

Fall 2015 patterned and forged mild steel plate, paint (private collection) A number of elements within

this series continues : torch cut edges, decorative lines

flattened, dishing and raising plate. An extra addition

here is the use of 'dry rub' paint. A dark green paint was

rubbed over the textured surface, then wiped clean. This

results in subtle colour, mainly caught in the lines and

forge marks.

26 x 21 cm, top edge 8 cm

|

|

Fall 2008 forged bloomery iron (purchased for use in a feature film) 'Offering Bowl' is forged from part of the 'Resurection'

Bloom made at in 2005. More Details available on 'Hammered

Out Bits' |

||

|

Summer 2011 forged bloomery iron (purchased for use in a feature film) The parent bloom was created at the 2005 Smeltfest event.

The metal itself was made from ore smelted using a direct

reduction furnace based on those from the Viking Age. |

||

|

Offering Bowl 2 /

Turf to Tools

Summer 2014 forged bloomery iron (In the collection of the Scottish Sculpture Workshop) The parent bloom was created as part of the Turf to Tools 1 project at the Scottish Sculpture Workshop (Lumsden, Scotland). The forge set up and equipment at SSW was at best minimal. As well, the coal available was not the best (high sulphur content). As a result, the forge weld from the original consolidation compaction and fold was not as secure as I had hoped. In the end this resulted in the 'double layer' effect during the dishing phase of the forging. |

|

|

Bloom Bowl 4

August 2014 forged bloomery iron (private collection) The starting iron bloom was produced in smelt #24, June 2007. The hemi-spherical mass was first flattened to a plate, with the ragged edges and textures of the parent bloom retained. For a full description of the complex creation process of this object, see the blog post. 15 x 12 cm, top edge 7 cm high

|

|

Who is Darrell Markewitz? |

|