2001 - 2008 : Go on HERE.

2008 - 2018 : Go on HERE

2018 - 2020 : Go on HERE

Experimental

IRON SMELTING

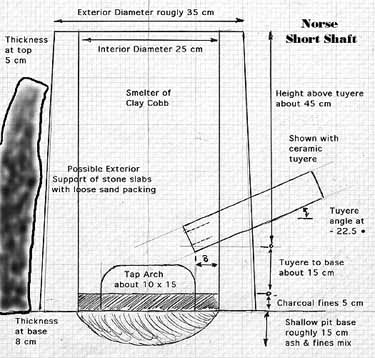

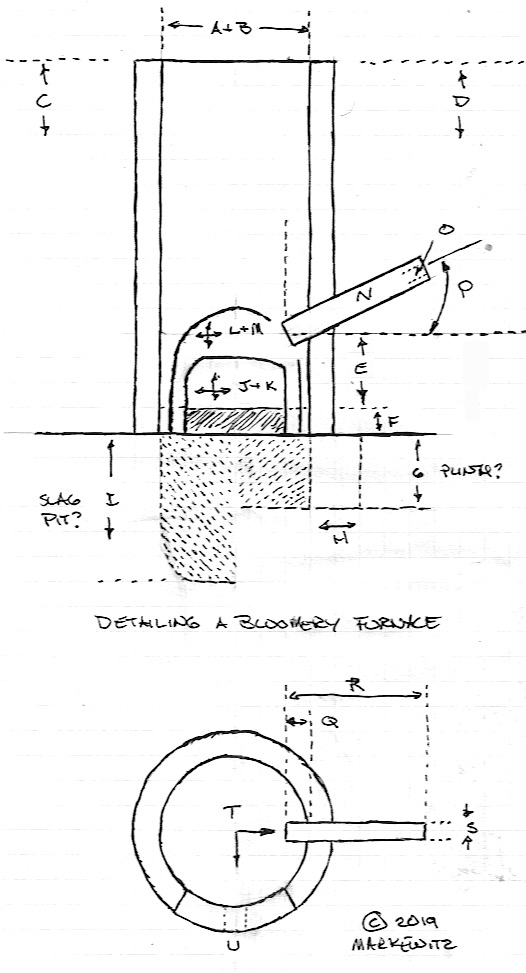

How did the Norse during the Viking Age make

iron blooms from bog ore?

Experimental Archaeology can give insight into the techniques

used in Northern Europe to operate direct reduction iron

smelting furnaces.

This is a record of the ongoing series by Darrell Markewitz,

assisted by members of the Dark Ages

Re-creation Company.

Wareham, Ontario, Canada is this centre for practical

research into Norse methods in North America.

Practical

Guides can be found lower down

Experimental Overview

Available in three forms:

|

The second is the text combined version

of the main data.

2001 - 2008 : Go on HERE. 2008 - 2018 : Go on HERE 2018 - 2020 : Go on HERE |

The third is an expanded data base

styled version of all of the recorded experimental

variables for each smelt. Go on HERE.

|

|

|

|

|

|

Stone

Slab with Blow Hole

October 2007 |

Demonstration

at Quad State

September 2008 |

Icelandic

Work Dynamic Test

October 2008 |

|

|

|

|

|

Vinland

1

June 2009 |

Cutting

a Bloom

(Vinland 1) |

|

|

|

|

|

|

Vinland

2

October 2009 |

Vinland

3

November 2009 |

'Econo

Norse' Furnace

November 2010 |

Quick Links to individual Smelt

Reports

Some of these links are away from this site.

Detailed Smelt

Reports

Overview Report / Smelt Sequence / Furnace Layout / Additional Materials Colour coding used below :

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Formal Papers /

Commentaries

|

Series Colour Code Applies |

| Continuing Adventures in

Early Iron Production An overview of experimental iron smelts, 2001 - 2008. An updating and revision of the paper delivered at the 'Friends of the Medieval Studies Society of the Royal Ontario Museum 1st Annual Symposium' in March of 2006. The Full text of the revised verson can be found at Continuing Adventures in Early Iron. The text of the original paper (35 page version) can be found at ROM - Adventures in Smelting . |

|

| Based on the remains at Hals Prepared with the assistance of Kevin Smith & Neil Peterson This is an 'in house' document outlining the archaeology and thought behind the Icelandic / Sod Smelter series Prepared October, 2008 Continue to 'An Icelandic Smelt' |

|

| Concerning the Shape of

Blooms Although originally published on the blog 'Hammered Out Bits' this short article has a more formal structure (footnotes and references). Original date February 9, 2010 The text can be found mirrored here - Shape of Blooms. |

|

| An Iron

Smelt in Vinland Converting Archaeological Evidence to Practical Method. Published in "Can These Bones Come to Life?", Cramer (editor) 2014 The full text of the revised verson (V3 - June 2010) Available as a PDF : Iron Smelting in Vinland. |

|

| 'But If

You Don't Get Any IRON...' Towards an Effective Method for Small Iron Smelting Furnaces. Published on in the EXARC Journal : issue 2012/1 Available as a PDF |

|

| Standardized

Reporting of Experimental Iron Smelting - a modest (?) proposal This article was sparked by discussions leading up to the orginally scheduled 2020 Woodford Furnace Festival (Ireland). Completed as a 'semi - academic' format, it was submitted and published in the EXARC Journal : issue 2021/1 Available as a PDF |

|

|

Westward Viking -

Iron

From Norway to Iceland ... to Vinland This presentation was prepared * for the 'virtual' 2020 Woodford Furnace Festival Video on YouTube * Equipment problems prevented delivery |

|

Now with 70% Less Clay!Experiments with

Viking Age Icelandic Turf walled Iron Smelting

Furnaces

This presentation was part of the

'virtual' 2021 EAC12

Conference Experimental Archaeology.

Prepared with the assistance of Kevin P. Smith and Neil Peterson. Video on YouTube |

|

| "Look

at the BONES!" Adding Bone in a Bloomery Iron Smelt This presentation was delivered (virtually) at the 2023 EAC13 Conference / Experimental Archaeology. Video on YouTube |

|

|

Icelandic Sod

Walled Iron Furnaces,

based on the Archaeology at Háls, Iceland This narrated Powerpoint style presentation was delivered (as recorded video) at the 2025 International Congress on Medieval Studies. This is an extension of the presentation above to include the November 2024 smelt, the last in this series. Video on YouTube |

|

|

Evidence of Absence Erosion of Bloomery Furnaces This report is an overview of an

ongoing process of observing a number of clay built

furnaces as they weather over time, started in 2004

and added to over the years.

This includes some observations that relate back to the continuing experimental series based on the Viking Age furnaces excavated at Hals, Iceland. Initially prepared May 2021, with additional images as time progresses. Continue to : Evidenceof Absence Part Two of this study is the

recording of two furnaces specifically left in their

use locations, being Smelt 90/D35 - Wind &

Weathering (October 2021), and the full Icelandic sod

build used for Smelts 88/D33 (June 2021), Smelt 89/D40

(September 2021) and Smelt 90/D40 (November 2024).

Initially prepared June 2025,

with additional images as time progresses.

Continue to : Evidence

of Absence - Part Two

|

|

|

Stacking Up

On constructing clay furnace walls This report is a consideration of

what has been learned from the construction of a large

number of clay mixture furnaces over the last two

decades.

This includes some observations that relate back to the continuing experimental series based on the Viking Age furnaces excavated at Hals, Iceland. : Prepared August 2021 Continue to : Stacking Up |

|

|

Into Phase 3 Continuing experiments with iron smelting based on Hals, Iceland This commentary is a re-evaluation of

the Icelandic series, looking again at the

archaeology, now with an additional 15 years of iron

smelting experience.

This includes discussion of how we are approaching the next series of experiments, testing elements suggested by the Viking Age furnace complex at Hals, Iceland : Prepared Summer 2021 Continue to : Phase 3 |

|

|

Experiments with

Viking Age, Icelandic, in collaboration with Neil Peterson This is a modified version of the more complete formal paper, currently under preparation, omitting the section to be contributed later by Kevin P. Smith. Presented here is a 'web integrated' text, describing in considerable detail the individual experiments, and including a larger series of images than are likely to be seen in the future published paper. Continue to : Experiments

with Icelandic |

|

|

Archaeology,

Experience and Experiment : with contributions by Neil Peterson

and Rey Cogswell

This is an expanded version of the formal paper

submitted for inclusion in the upcoming volume Can

These Bones Come to Life?, including additional

photographs - combining a number of individual reports

prepared over 2021. Continue to : Archaeology,

Experience & Experiment |

|

|

How Dense Are You?

: with contributions by Neil Peterson Charting the density of a sample group of 30 iron blooms, created over a span of roughly 15 years during experiments aimed at understanding iron smelting furnaces, and comparing these to a number of artifact samples. Continue to : How Dense |

|

| 'That Which Remains' : Signs from Bloomery Iron Smelting Initial Compaction As a guide to field archaeologists

excavating iron smelting sites, this series will

illustrate the actual production of blooms using small

direct process ‘short shaft’ furnaces. This should

provide insight into the physical traces that might be

expected, and how these relate to the various stages

in the overall process from ore to bloom and into

finished working bar.

Once a bloom is extracted from the smelting furnace, the next step is to undertake an initial surface cleaning and compaction process. A detailed examination of the debris field created during the initial compaction process carried out during smelt # 91/D37 Continue to : Initial

Compaction (PDF)

|

|

|

35 to Bloom

A short report on the conversion of a single bloom, from Smelt 35 at Iron at Thy (2008) which was rendered into a working bar on August 13, 2024, with the assistance of Neil Peterson. Continue to : 35 to

Bloom

|

|

|

Turf to Tools - Final

Reports

|

|

|

Experiment,

Archaeology & Art - The Turf to Tools Project (2023)

This is the full version of the paper behind a presentation at the European Archaeology Association EAA23 conference at Belfast, Ireland, September 1, 2023, Session 729 - EXARC: Reconstructing Past Narratives Through Experimental Archaeology. A shorter version, covering just the experimental iron smelting and bloom to bar processes (less lavishly illustrated) is pending publication. |

|

|

Turf to Tools - An

Artisan's View (2016)

Originally prepared as a contribution to a planned, and never completed, book to accompany the project. (much of this earlier material continues in the full paper) Continue to : An Artisan's View

|

|

|

Bloom to Bar to Axe

(2023)

A photo essay detailing the conversion of T2T blooms into working bars, then those bars into the finished reproduction of the Rhynie Man Axe. Continue to : Bloom - Bar - Axe

|

|

|

Who is the Rhynie

Man? (2014)

A speculative piece, originally prepared as a contribution to a planned, and never completed, book to accompany the project. Continue to : Rhynie Man

|

|

|

||||

Is my BLOG - on it you will find a regular series of short postings on various aspects of Experimental Iron Smelting Go to 'Hammered Out Bits' |

||||

The following articles are from the very start of the

Experimental series, and are considerably dated. (Included

to document the entire process undertaken.

|

|

Air Flow Rates

A table of measured rates from our standard equipment (Revised October 2007) Go on Air Rates. |

Bellows Air Test

Measuring Operator rates using a reconstructed Norse blacksmith's bellows (Report October 2007) Go on Bellows Test. |

|

Iron Content of Ores

A table of major components in our standard ores (Revised 2021) Go on Iron Ores. |

|

|

Charcoal Pit Burn

Experiment

Photo Essay - 'a demonstration of an experiment' (July 2007) Go on Charcoal. |

'Heat by Colour' A visual reference - Colours |

| 'Bloom to Bar' Table of measured results to % Yields (December 2018, largely based on the 2012 OAC Project) Go on to Bloom 2 Bar |

'Smelting with Sven &

Yorgi' A 'thought experiment'. How would the process of smelting iron be described - in the Viking Age? Go on to Sven & Yorgi |

|

Details

on how to build small scale test bed and teaching

equipment

- made from easily available materials :

45

Gallon Drum Charcoal |

||||||||

|

|

The Turf to Tools - TWO

project, at the Scottish Sculpture

Workshop, September / October 2016, Those interested in tracing the activities,

check the many postings on the blog over September

& October,

2016 |

|

The Turf to

Tools - Part ONE project, at the Scottish Sculpture

Workshop, August 2014,

was in part supported by a Travel

Grant from the Canada Council for the Arts |

|

||

|

It was supported by a Crafts Projects - Creation and Development Grant. The Ontario Arts Council is an agency of the Government of Ontario. The purpose of the grant was to cover three months dedicated time to allow development of a practical understanding of how to covert raw blooms into working bars, and if time permits, into finished objects. Part of the process will be to document the ongoing project, and publish the results via a dedicated blog, this web site, and through demonstrations, formal papers or journal articles. |

|

Go on Links |

This roughly 20 hour session will involve the student in the construction and operation of the 'EconoNorse' small scale iron smelter. On Friday evening students will cover the theoretical and historical background of smelting iron: ores, furnaces, process, equipment. Saturday students will build the furnace itself, plus prepare charcoal and ore. An early start for a LONG day Sunday will start with the pre-heating the furnace. The actual process of the smelt takes roughly 6 - 8 hours. After this, the resulting iron bloom will be extracted from the furnace, and given a primary consolidation. The iron produced will be cut to sections and shared between the participants. This program does not require any previous metalworking experience, and is of interest to students of history as well as blacksmiths. |

|

pull out guide

|

the Wareham Forge

|

Who is Darrell Markewitz? |